Decomposition Library is a collection of textile decomposition experiments, observing and cataloguing gradual decomposition of textiles and biomaterials in compost.

/

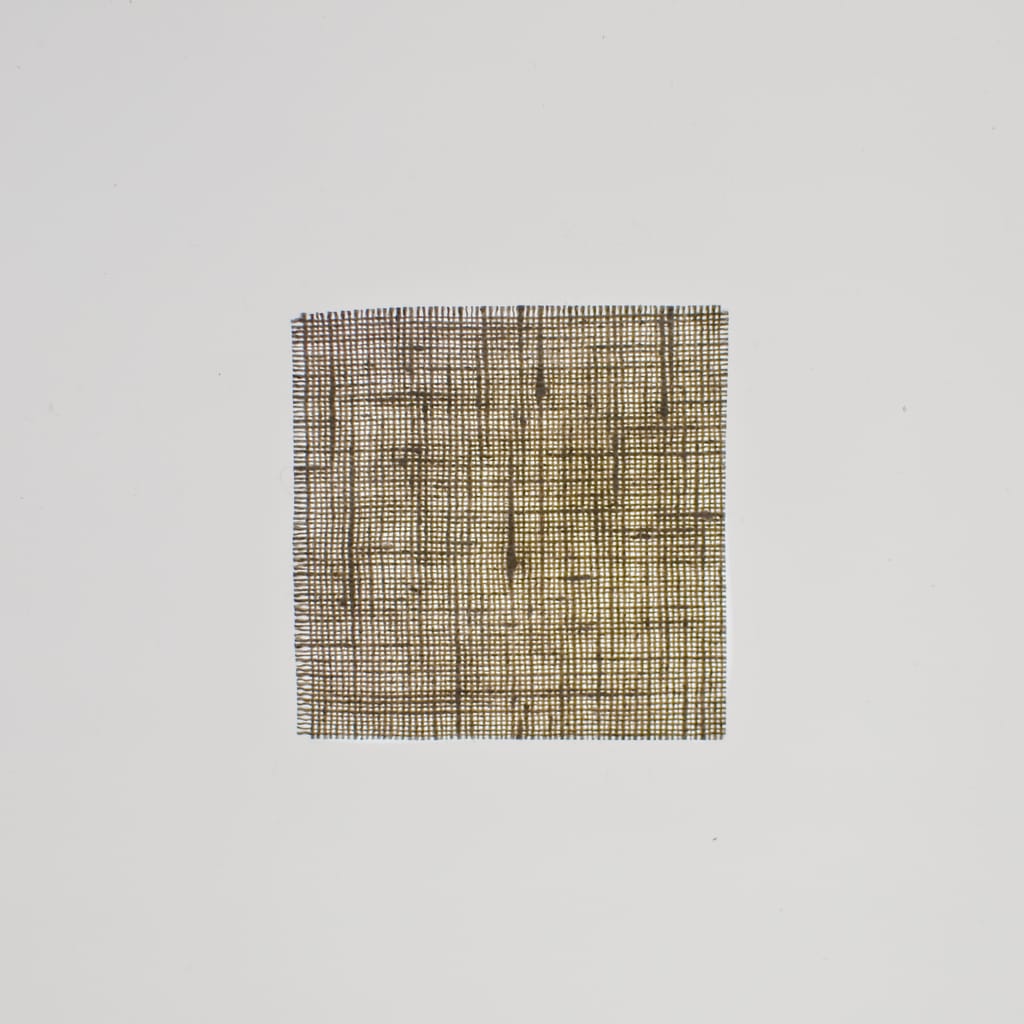

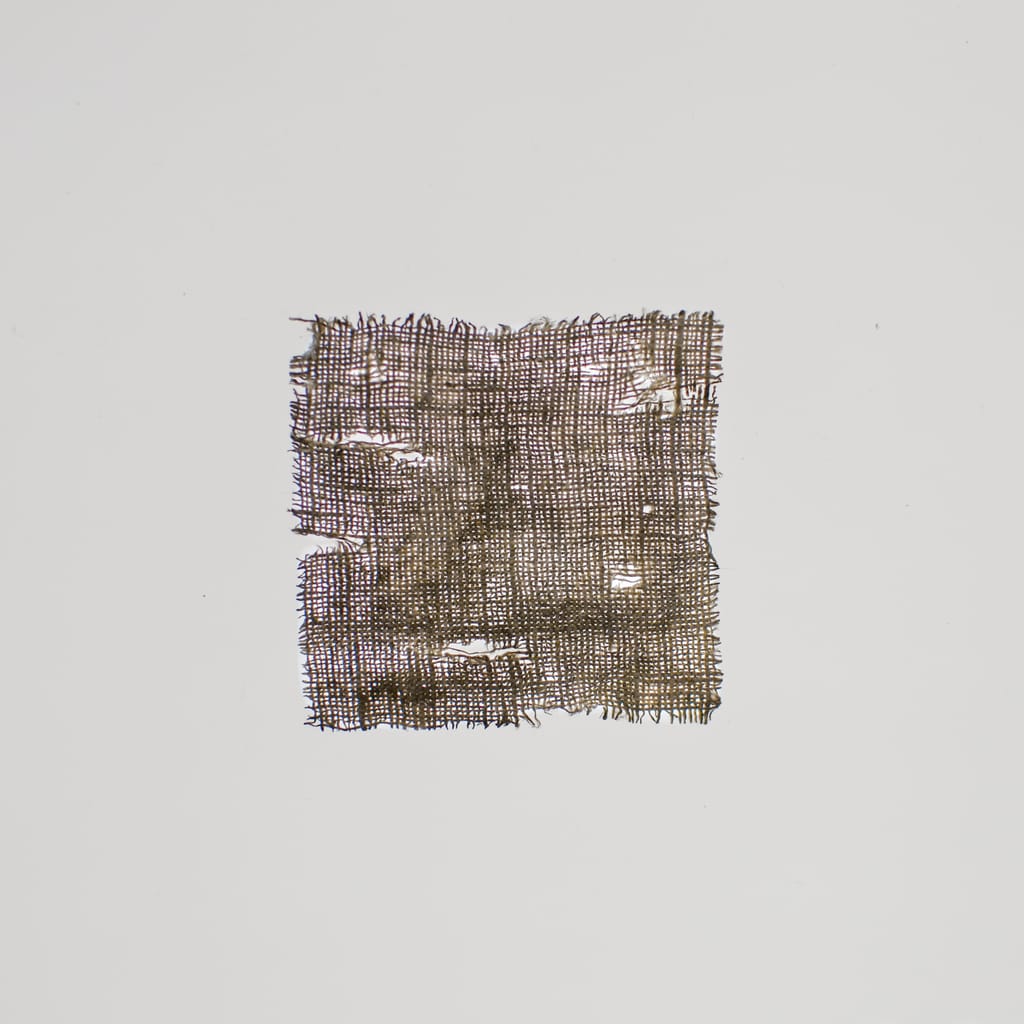

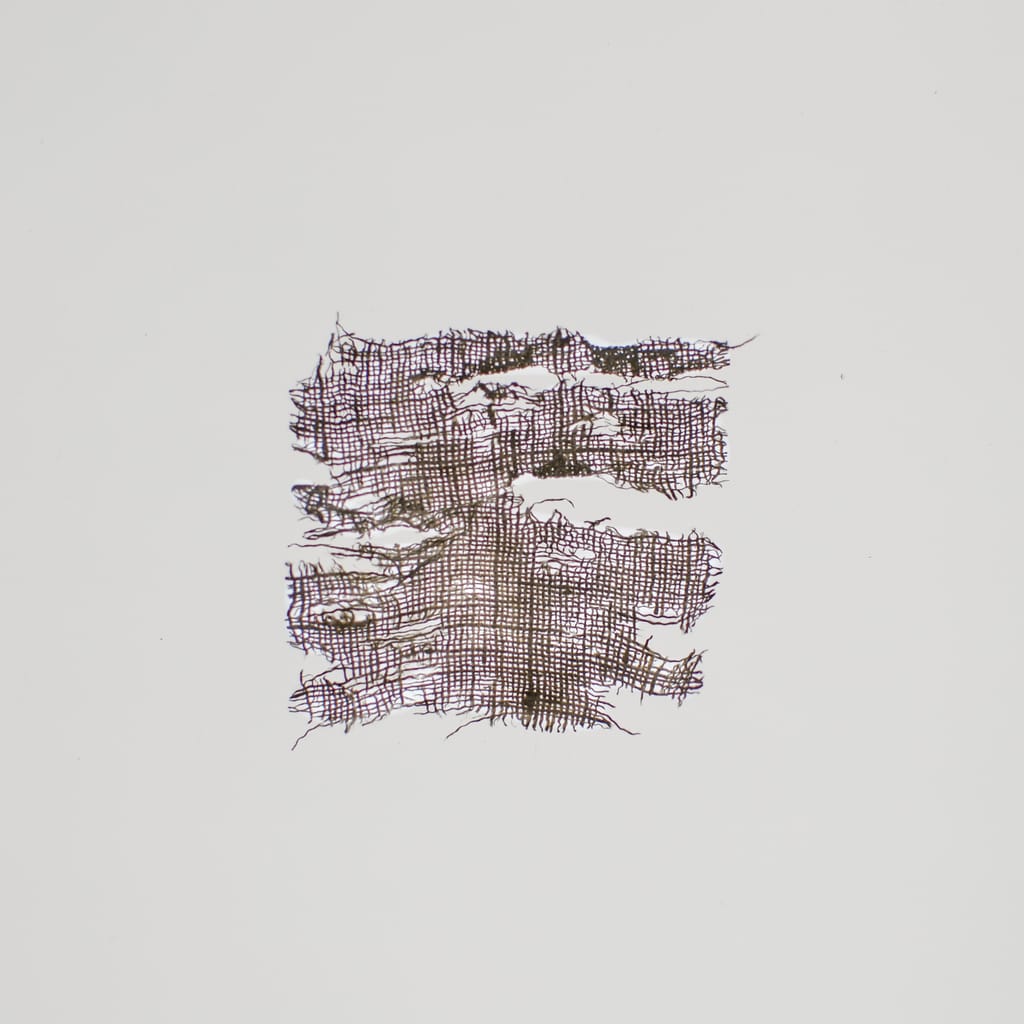

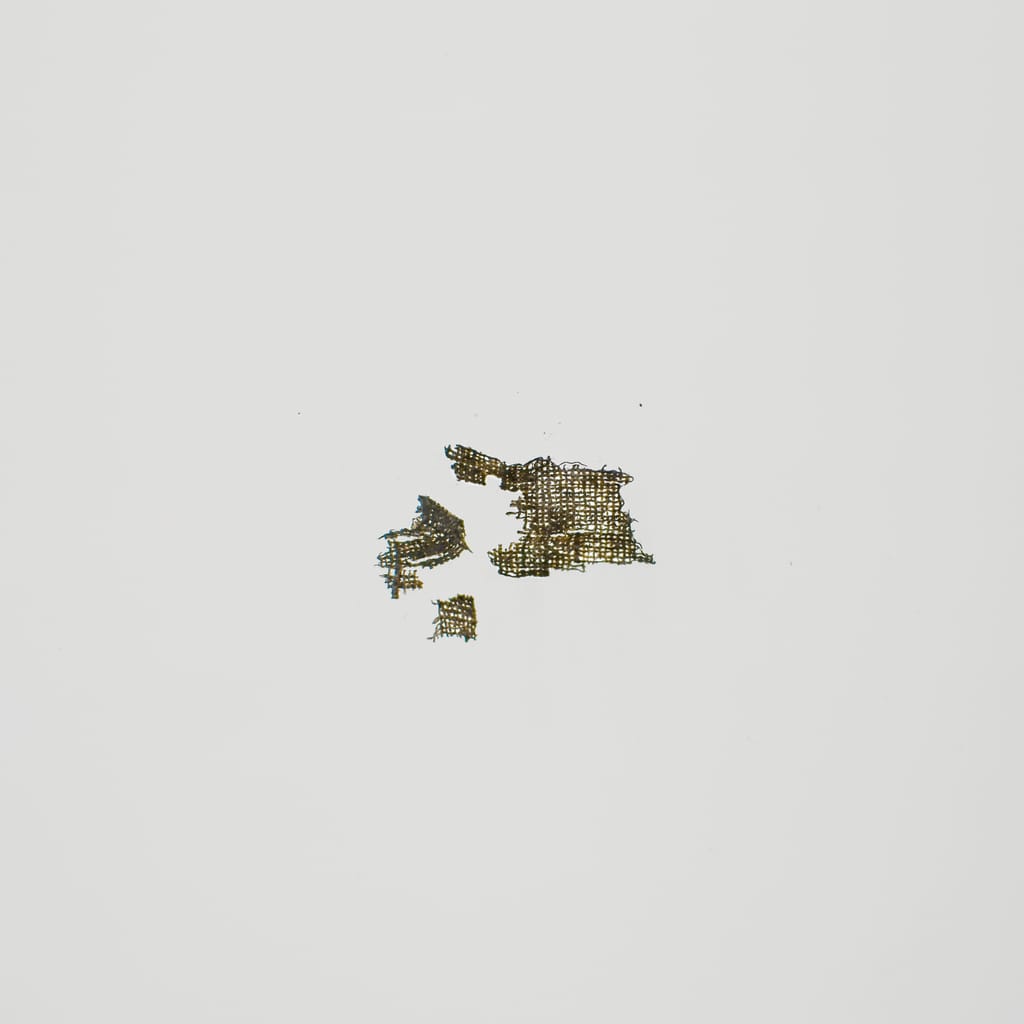

Bamboo 01

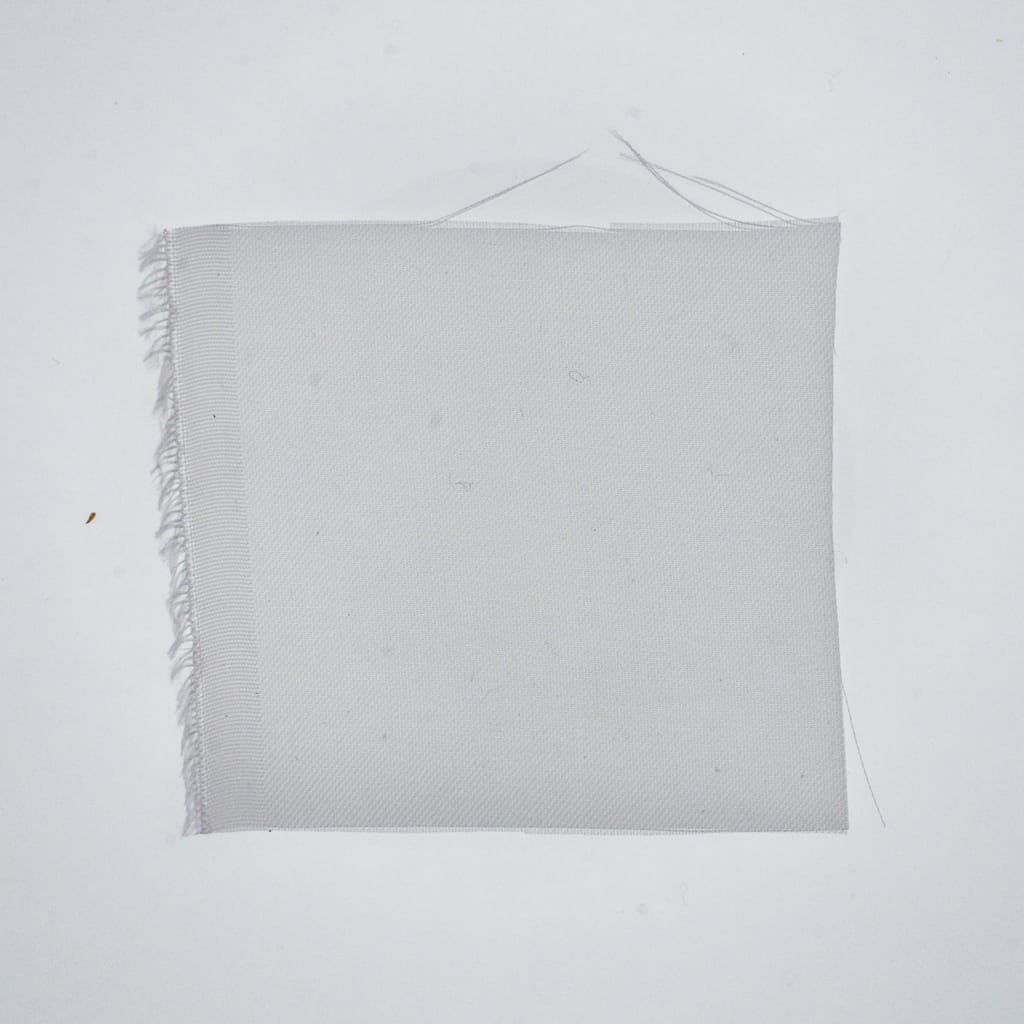

ID:Bamboo 01

Date:22.08.2023 - 12.09.2023

Material:100% Bamboo

Fibre:Regenerated cellulose

Temperature:29°C

Size:

75x75mm

Notes:

Weight: Approx. 120gsm

Original colour: White

<u>More about Bamboo:</u>

Stretchier than cotton, bamboo is a strong material obtained from the bamboo stalks and leaves. Bamboo fabric can be manufactured in 2 different ways - the most common being as a regenerated cellulosic fibre (viscose), extracted from the stems and leaves through a process of alkaline hydrolysis into a pulp. The other one by mechanical crushing and retting.

<u>Properties:</u>

Properties of what's referred to as bamboo fabric depend on its processing method. In general, bamboo fabric is stretchier and can be finer than cotton, which makes it its favoured dupe. Though its supposed antibacterial claims in finished fabrics and garments are not based on science, as only the raw bamboo product has antibacterial properties.

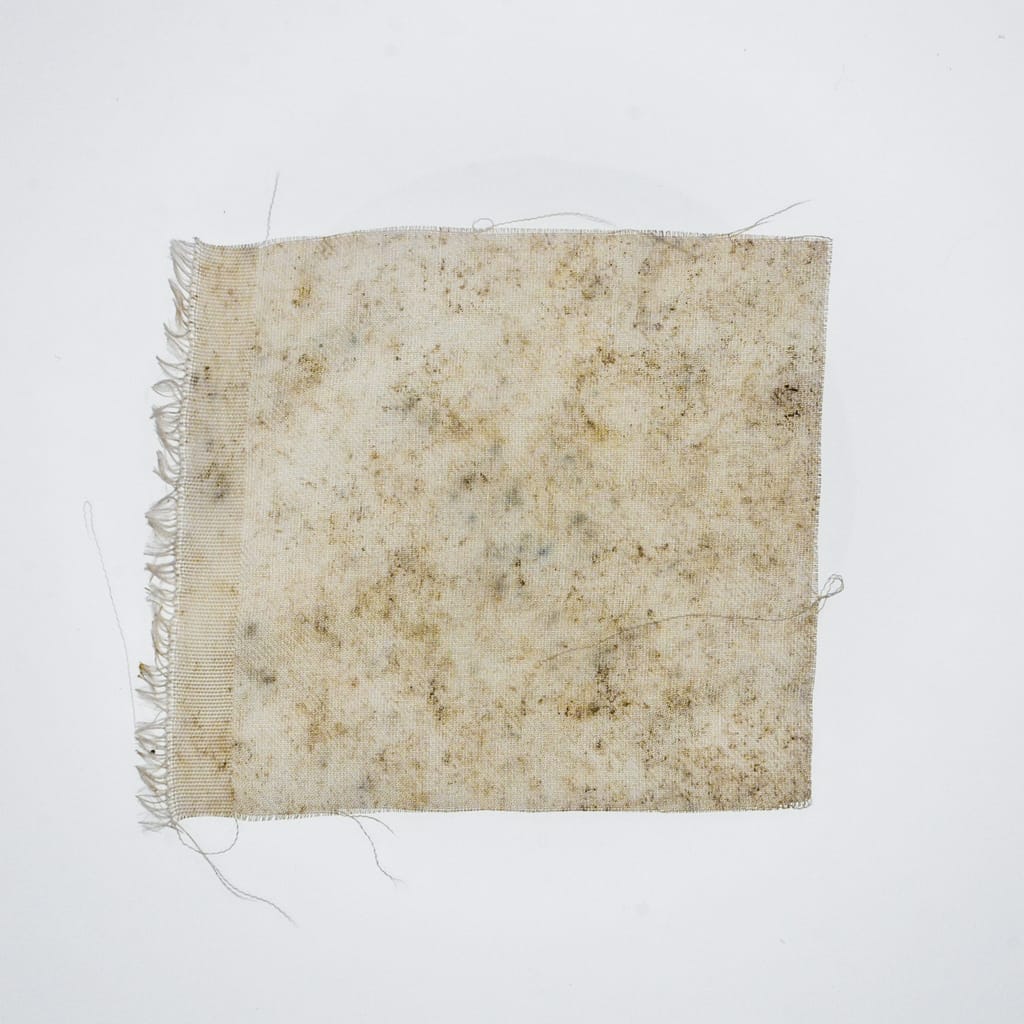

<u>Decomposition:</u>

The tested sample was bleached bamboo fabric (made as a regenerated cellulose fabric) and decomposed in mature compost in 29°C for 4 weeks. From week 1 obvious holes started appearing, showing how fast the structure decomposes. Other than that, one can observe obvious staining of the fabric, because of the presence of pigmented bacteria and fungi, as well as the pigments from microbial decay. Week 2 already showed heavy fragmentation and by week 3 only small pieces of bamboo fabrics were retrieved.

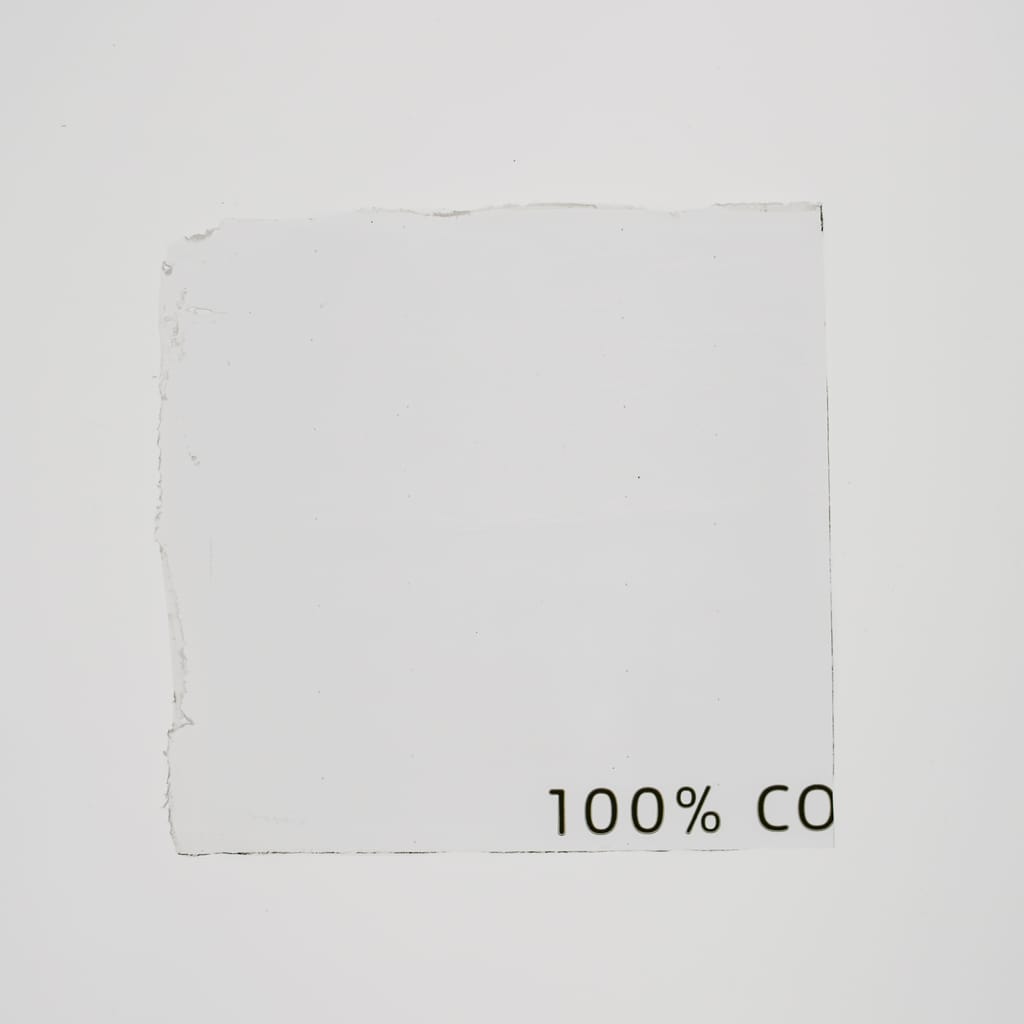

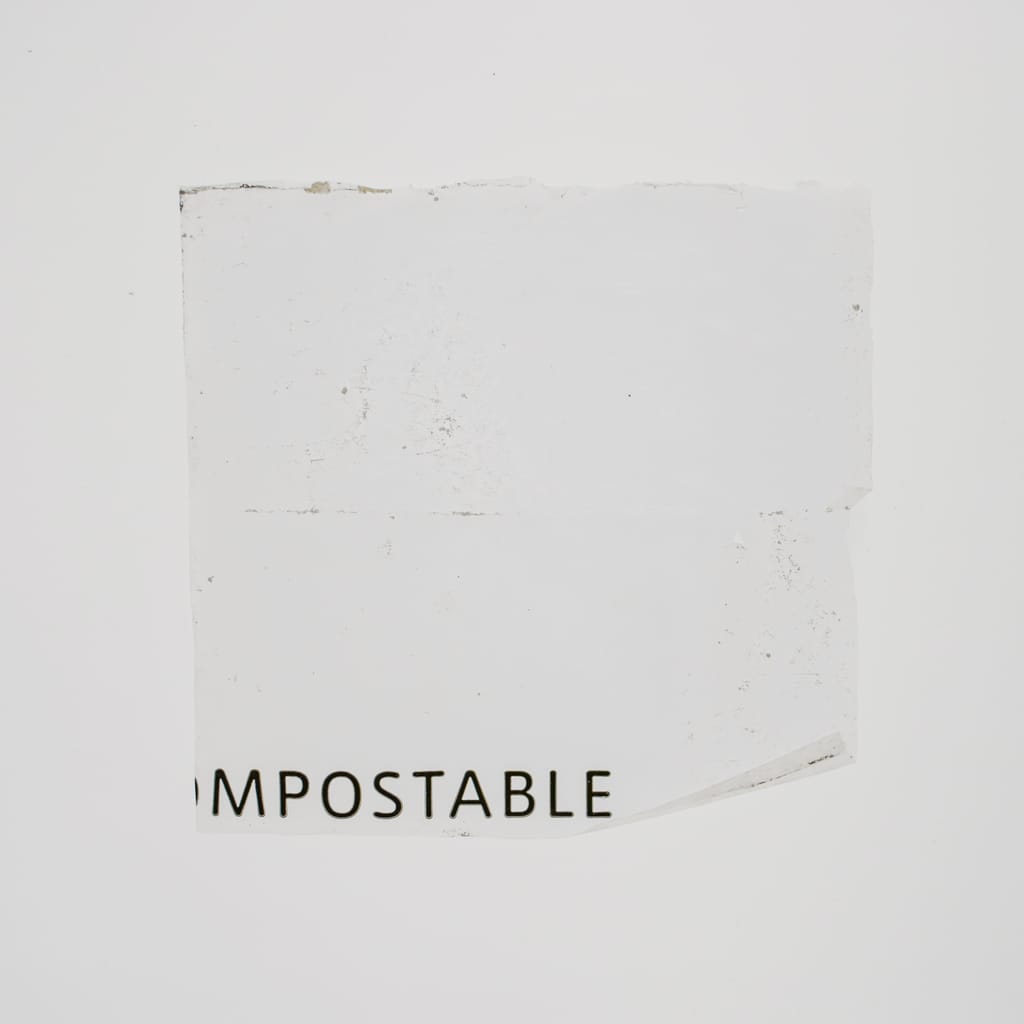

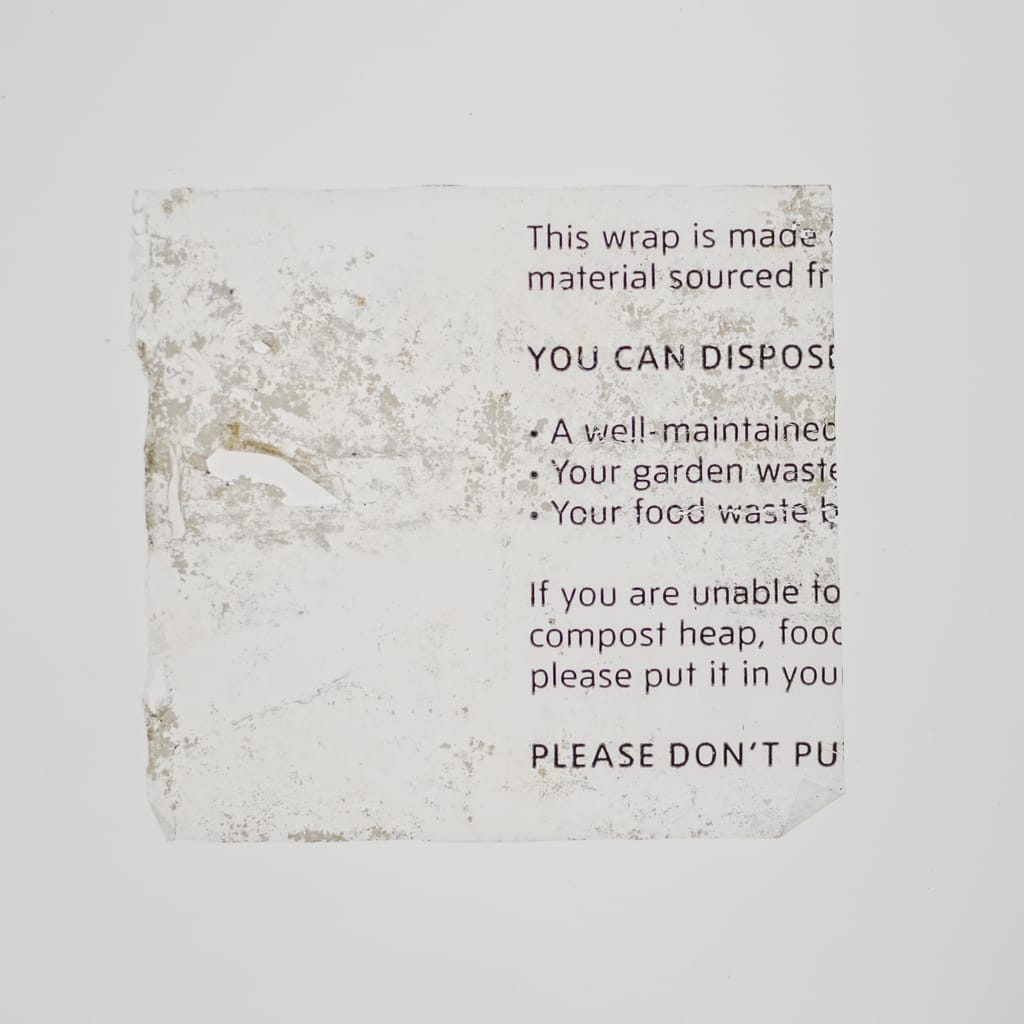

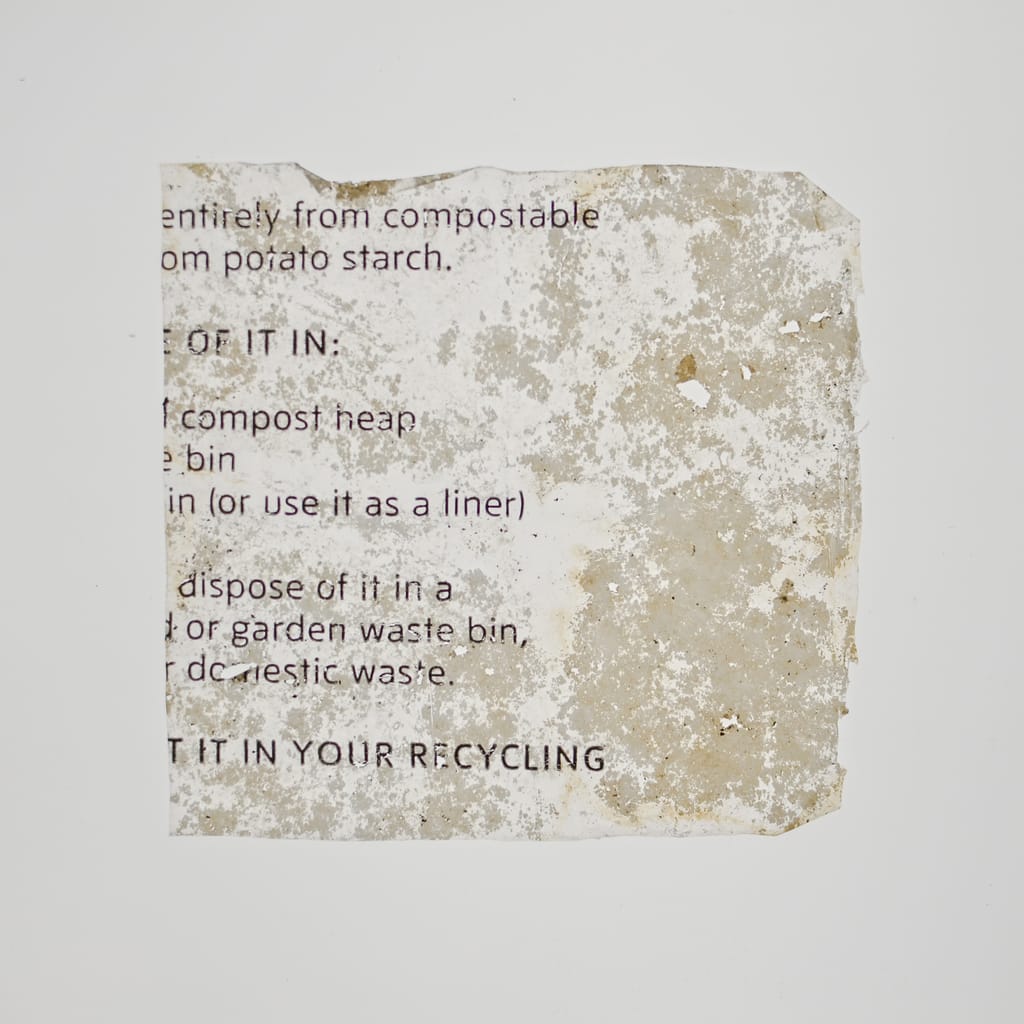

Bioplastic 01

ID:Bioplastic 01

Date:24.09.2022 - 29.10.2022

Material:Bioplastic, Potato Starch Based

Fibre:N/A

Temperature:29°C

Size:

75x75mm

Notes:

Certified Home Compostable (TUV Austria). Originally a wrapper for Tate Newsletter.

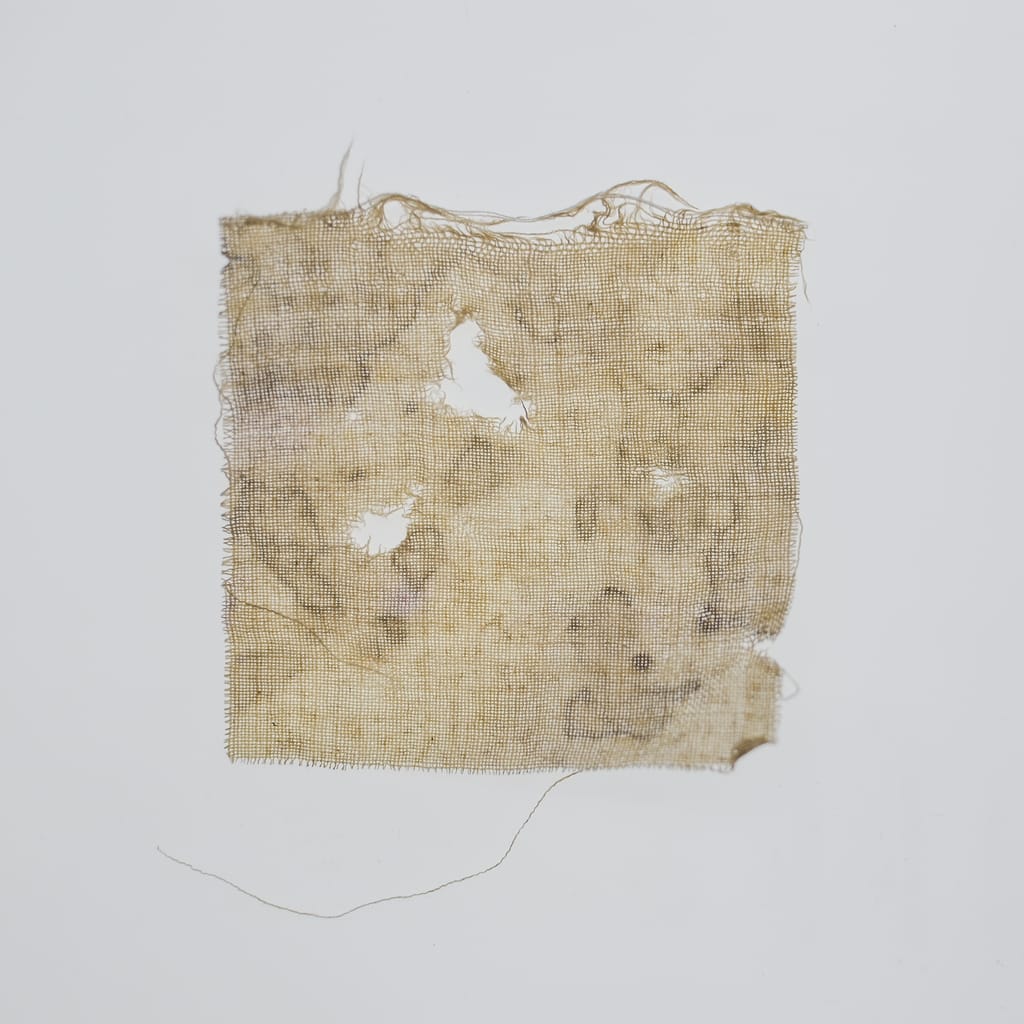

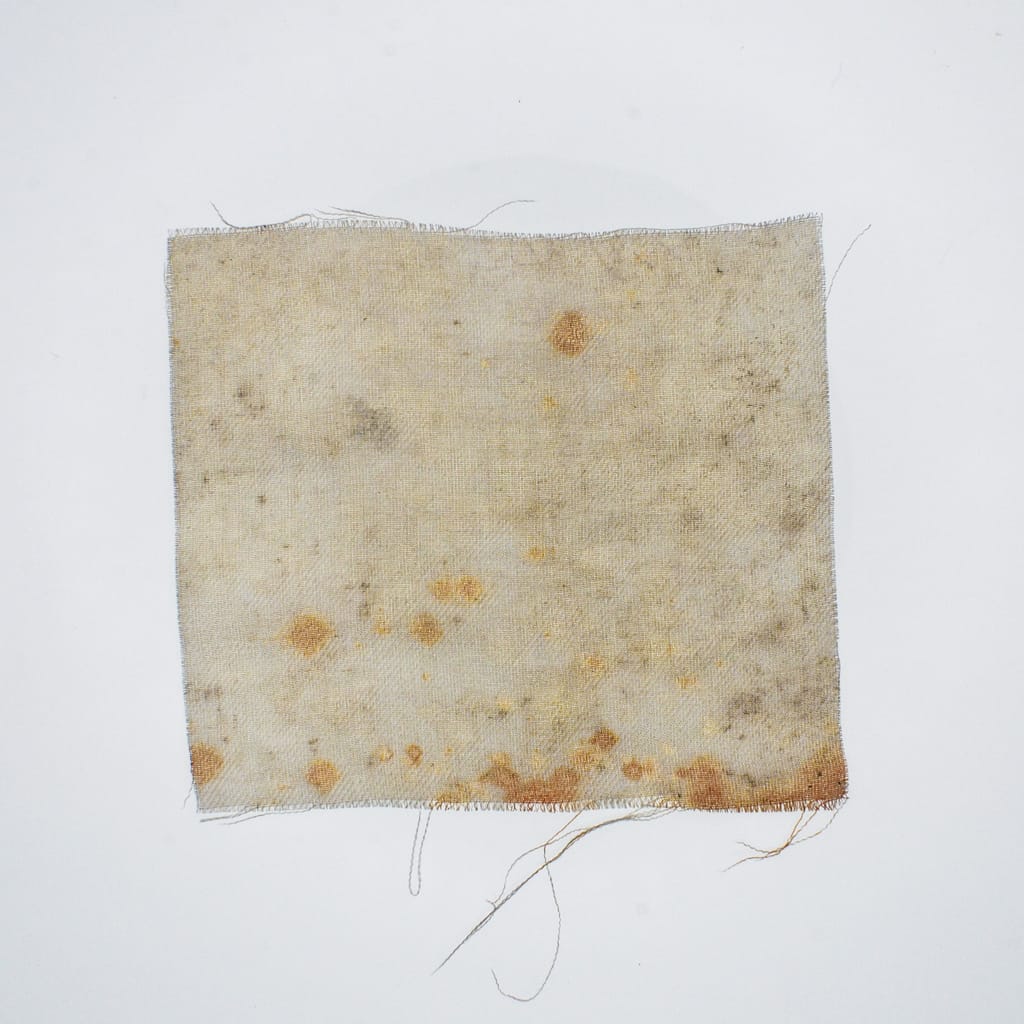

Cotton 01

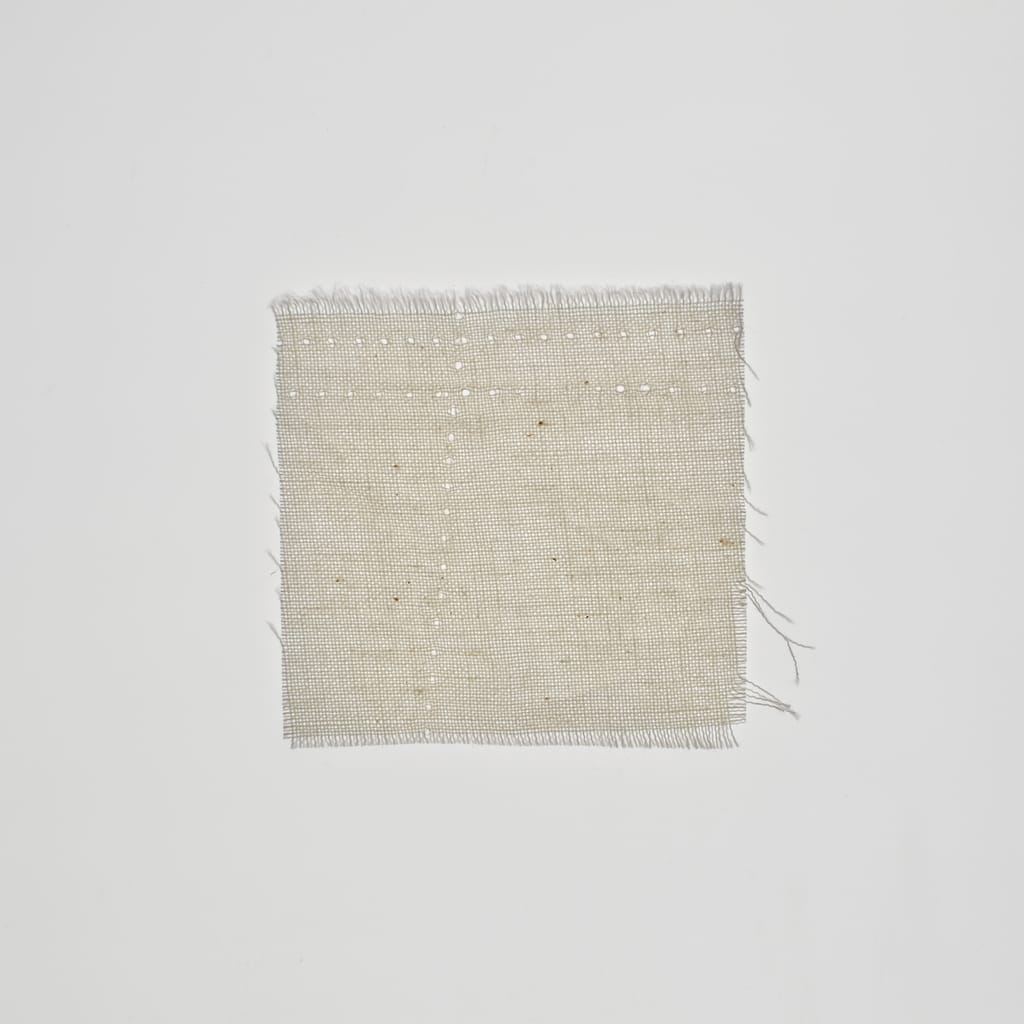

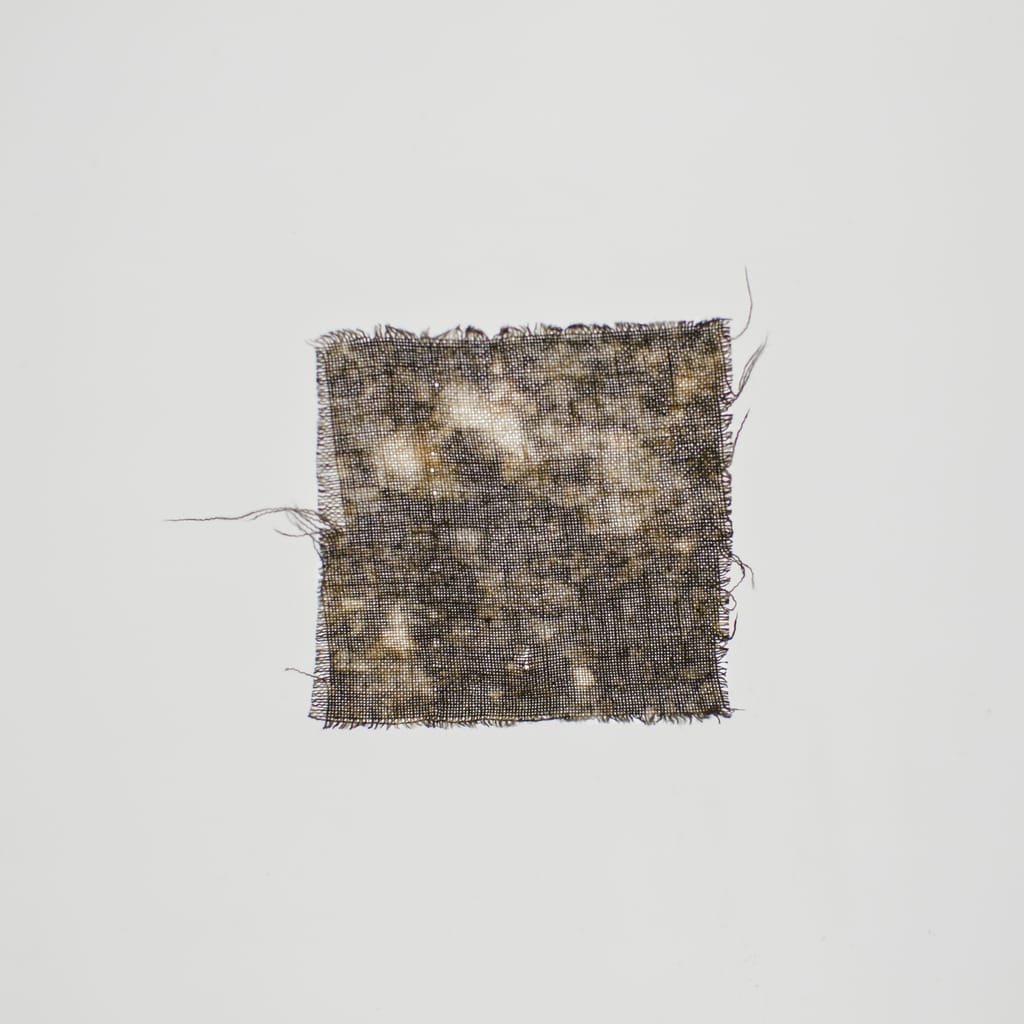

ID:Cotton 01

Date:2021 - 2021

Material:100% Cotton

Fibre:Natural Cellulosic

Temperature:29°C

Size:

50x50mm

Notes:

Original colour: Ecru

Light-weight, unbleached cotton, GOTS certified, license number CERES-074

<u>More about Cotton:</u>

By far the most recognised and widely accessible plant-based fabric, cotton is soft, breathable, and highly absorbent. It is estimated that around 75% of world's clothing products contain some amount of cotton. The fabric's fibres grow in a boll - the part of the cotton plant with fluffy fibres and the seedpod. The resulting fibre and is almost pure cellulose, making it soft and fluffy.

The processing is not as labour intensive as with bast fibres (linen etc.), though growing cotton is very water intensive and requires a lot of land. Currently it is the cheapest natural fibre to produce, which often lends to exploitative practices in its supply chain.

<u>Properties:</u>

What makes cotton so desirable, other than its low cost, is its ease of processing and its proprieties. It has excellent moisture wicking properties, meaning that it absorbs water well, but it also dries quickly. Other than that, it's soft to the touch and drapes well, making it a favoured material for clothing.

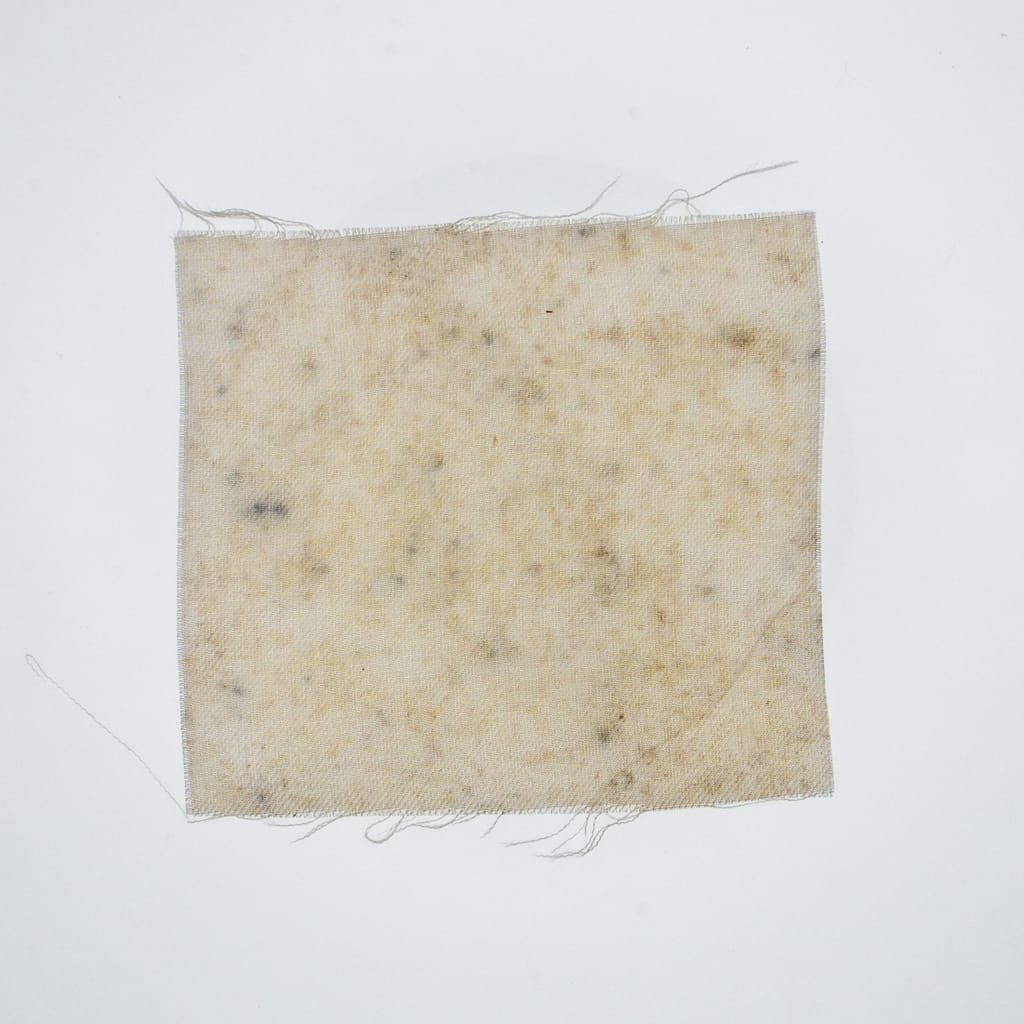

<u>Decomposition:</u>

Unbleached and undyed organic cotton decomposes fast in mature compost in 29°C, over 4 weeks. What's obvious during the process is the staining of the fabric that occurs, because of the presence of pigmented bacteria and fungi, as well as the pigments from microbial decay. The structure of the fabric weakens significantly from week 2 onwards, resulting in strong fragmentation around week 3.

Organic, unbleached, and undyed cotton fabric should be safe for home composting.

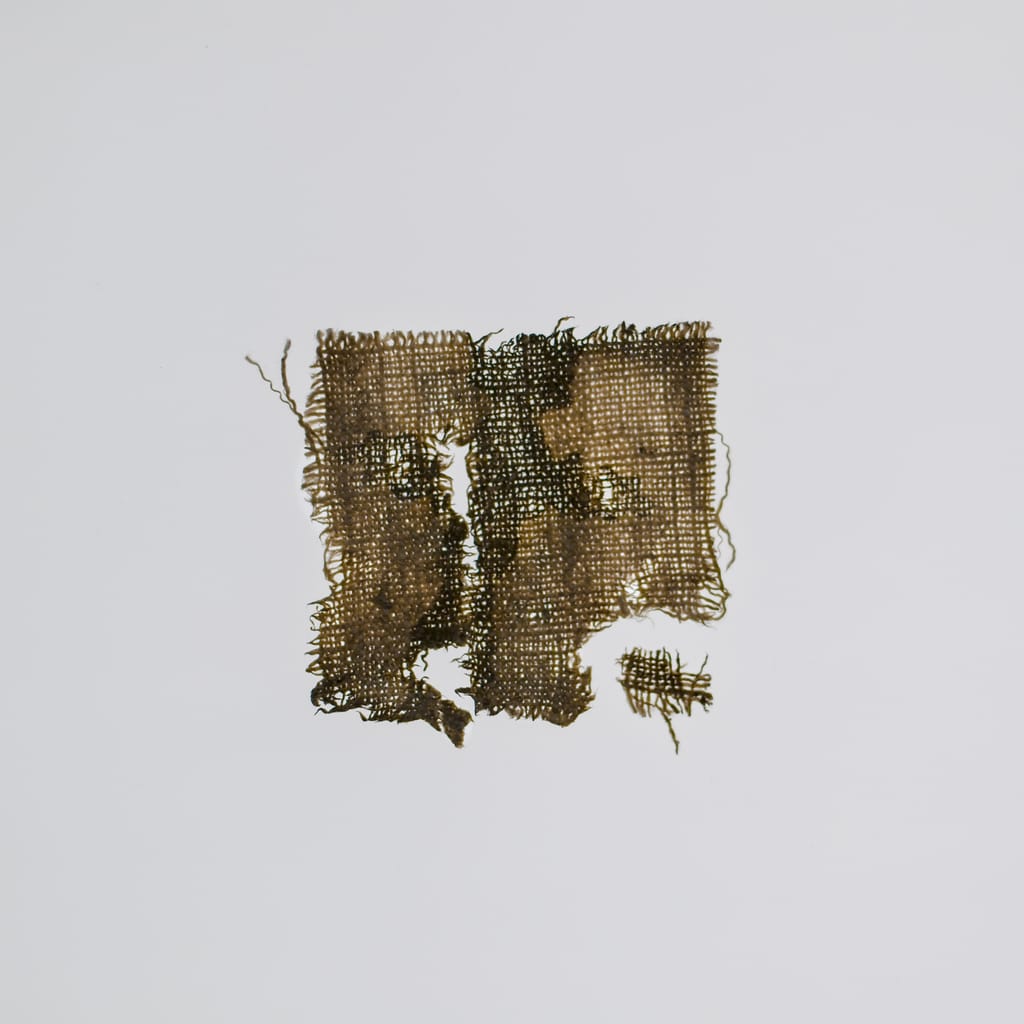

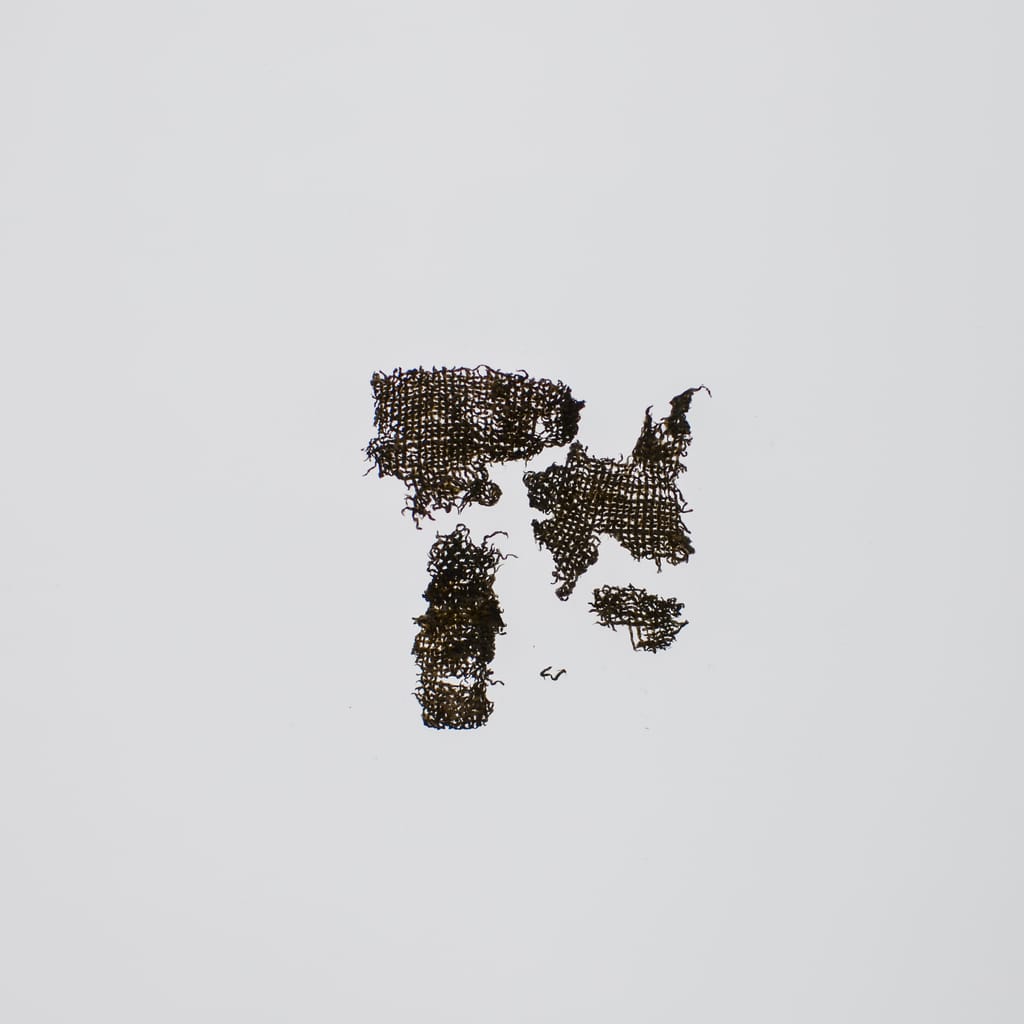

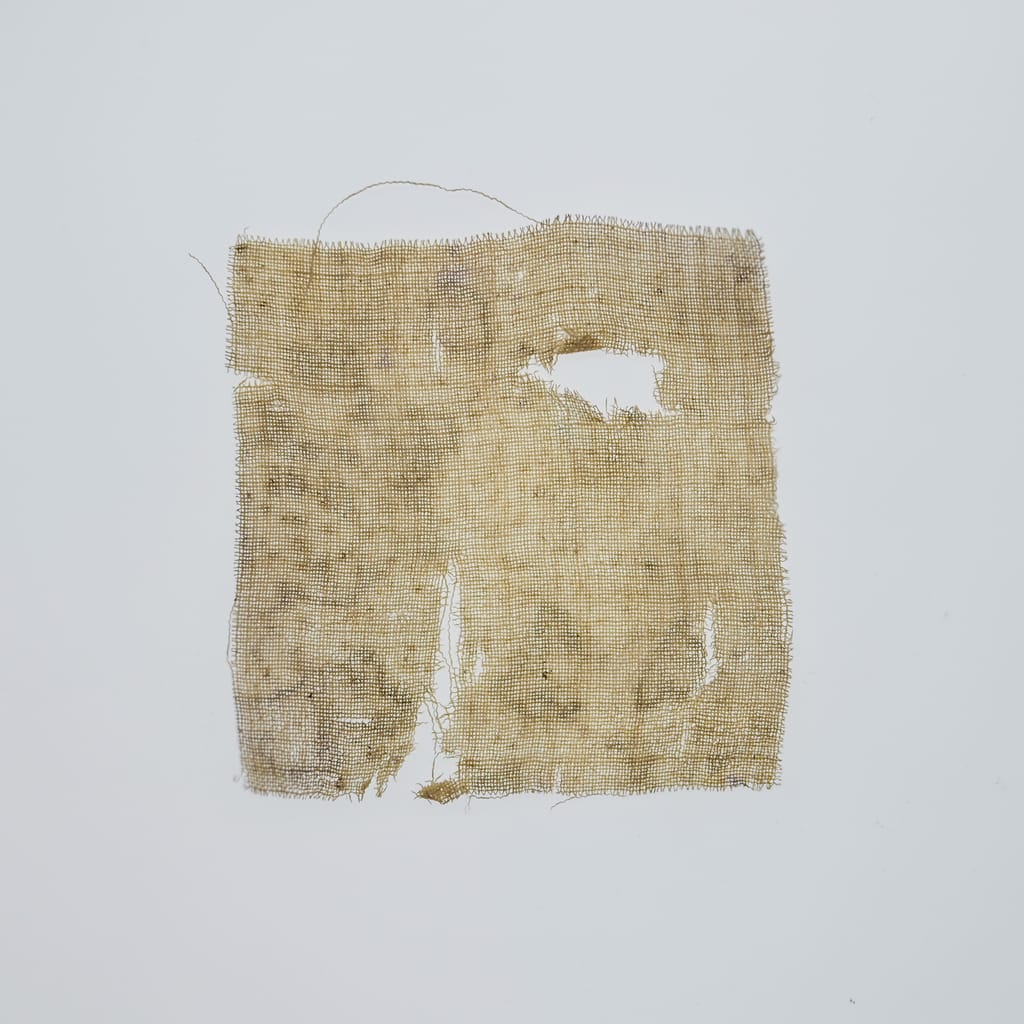

Hemp 01

ID:Hemp 01

Date:2021 - 2021

Material:100% Hemp

Fibre:Natural Bast

Temperature:29°C

Size:

50x50mm

Notes:

Original Colour: Ecru/beige

Heavy-weight, unbleached hemp textile.

<u>More about Hemp</u>

Hemp fabric is made using fibres from the stalks of the Cannabis sativa plant.

<u>Properties:</u>

It is widely recognised for its great tensile strength and durability. Unlike cotton, it's not susceptible to shrinkage and it doesn't weaken when washed, a feature which made this textile the primary material for sails and ropes for entire naval fleets.

<u>Sustainability</u>

Other than its mechanical properties, the hemp plant has excellent carbon sequestration properties, where one hectare of industrial hemp can absorb up to 15 tonnes of Co2. It's a very fast-growing crop, often considered an environmental super fibre, as it enriches the soil and adds rich organic matter to the topsoil, helping to retain moisture. It requires no pesticides or herbicides, controls erosion of the topsoil, and produces oxygen. It is a renewable resource that can be cultivated in as little as 100 days.

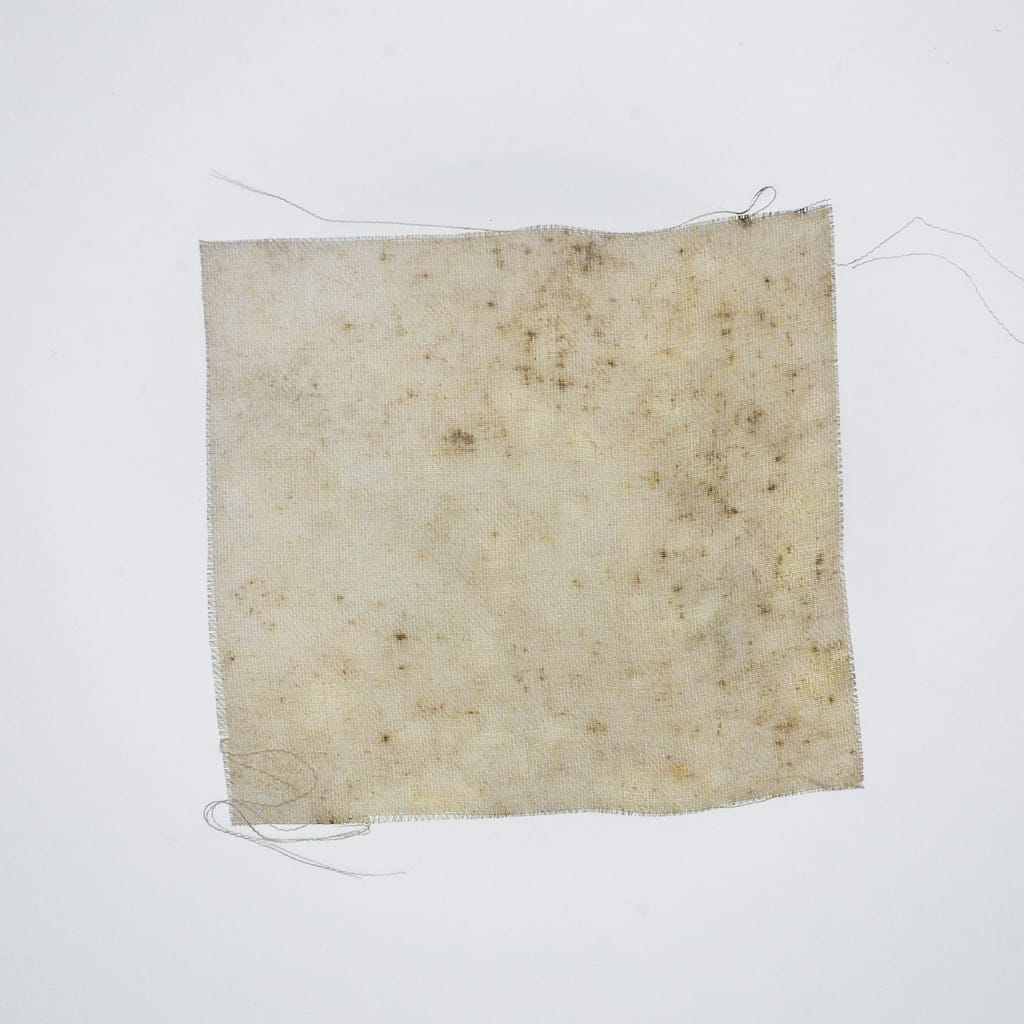

<u>Decomposition:</u>

Unbleached and undyed hemp decomposes quickly in mature compost under constant temperature of 29°C. Significant structural weakeninging can be observed from week 2, and by week 3 the tested fabric sample is heavily fragmented.

Organic, unbleached, and undyed hemp fabric should be safe for home composting.

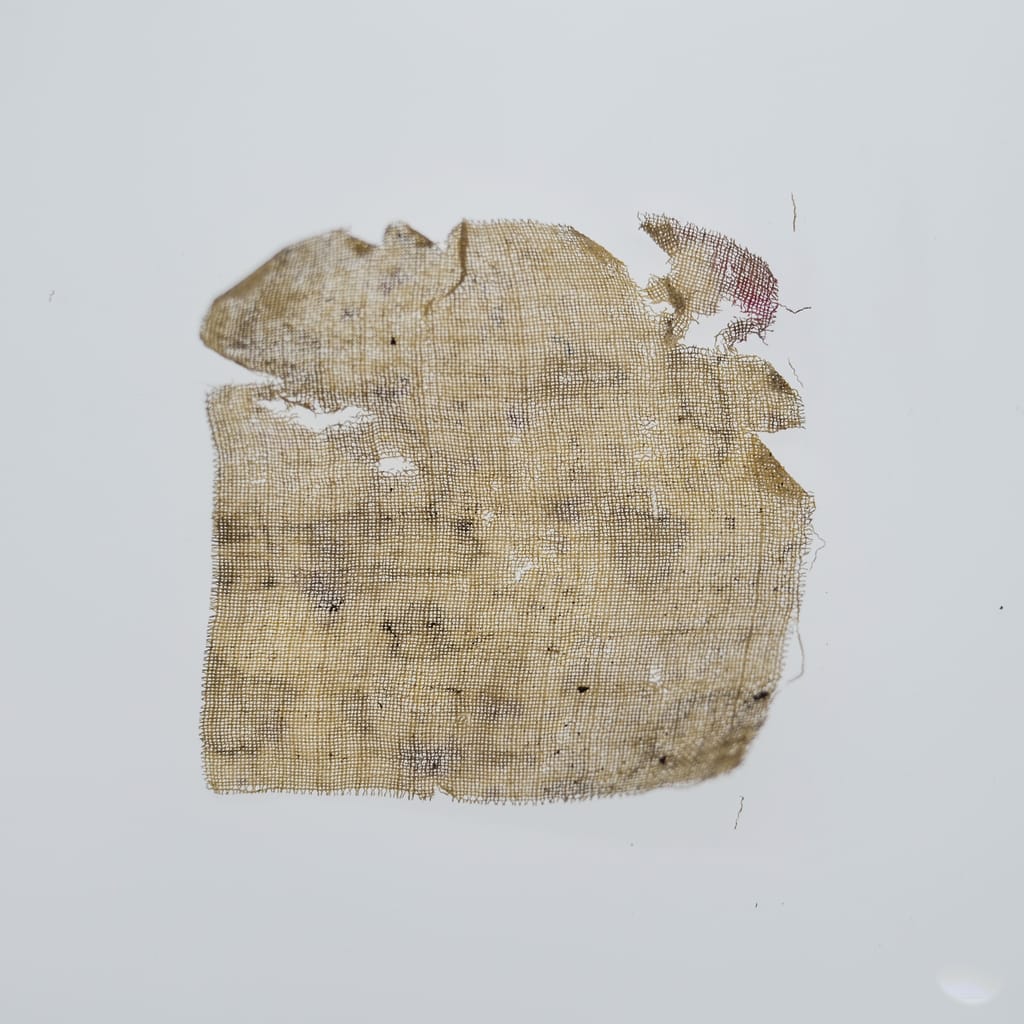

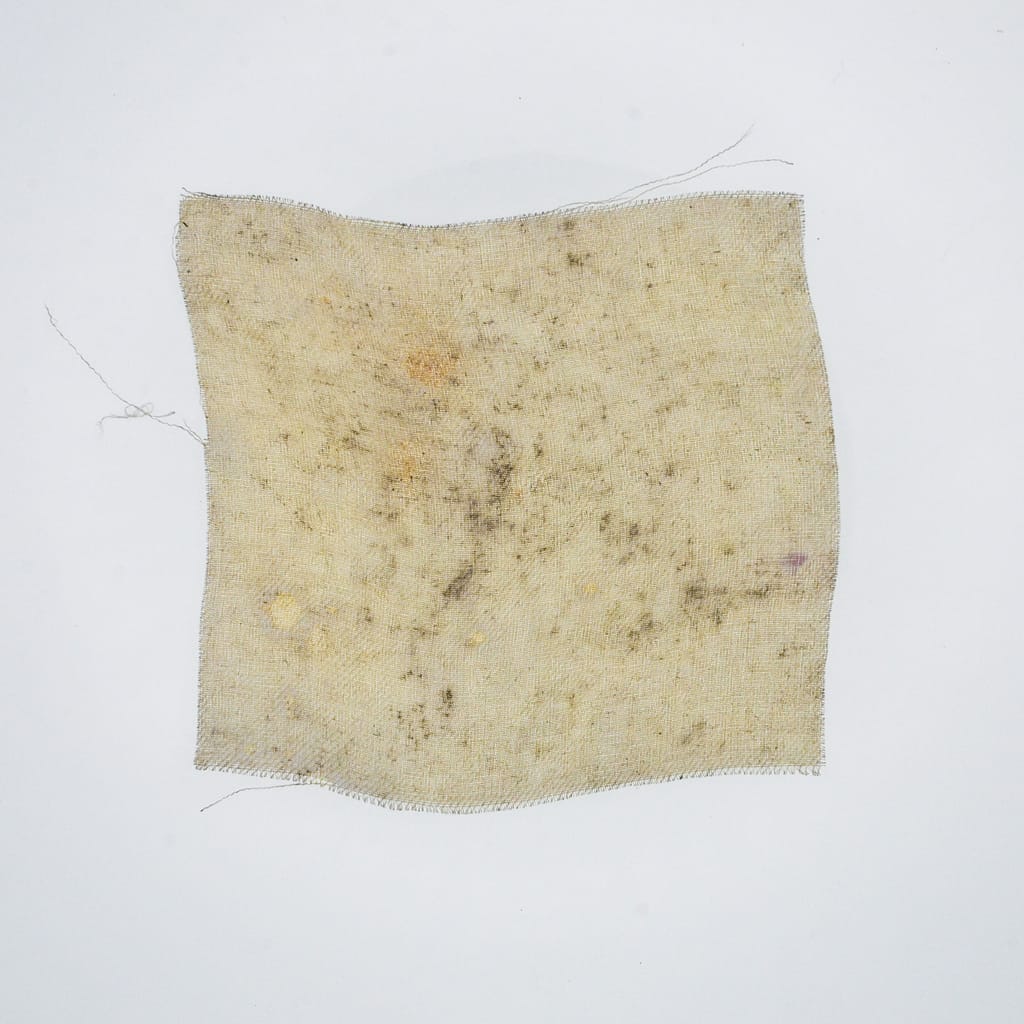

Linen 01

ID:Linen 01

Date:2021 - 2021

Material:100% Linen

Fibre:Natural Bast

Temperature:29°C

Size:

50x50mm

Notes:

Original colour: Light brown, unbleached

<u>More about Linen:</u>

One of the oldest found textiles, according to archaeologists, linen was first domesticated in ancient Mesopotamia.

The fabric is made from fibres derived from the stems of the flax plant, making it a bast fibre, extracted through a labour-intensive retting process. Despite its rich history, linen's central role in textile economy diminished, as cotton production became cheaper and easier, turning linen fabric into a comparatively niche product.

Organic, unbleached, and undyed linen fabric should be safe for home composting.

<u>Properties:</u>

Linen is a strong and durable fibre, though it has poor elasticity. What makes it unique is its breathability, which is described as cool to touch, making it an ideal material for hot and humid climates. Other than that, it's hypo-allergenic and anti-bacterial, making it perfect for people prone to skin sensitivities.

<u>Decomposition:</u>

Unbleached and undyed linen decomposes quickly in mature compost under constant temperature of 29°C. Significant structural weakening can be observed from week 1, and by week 3 the tested fabric sample is heavily fragmented.

Organic, unbleached, and undyed linen fabric should be safe for home composting.

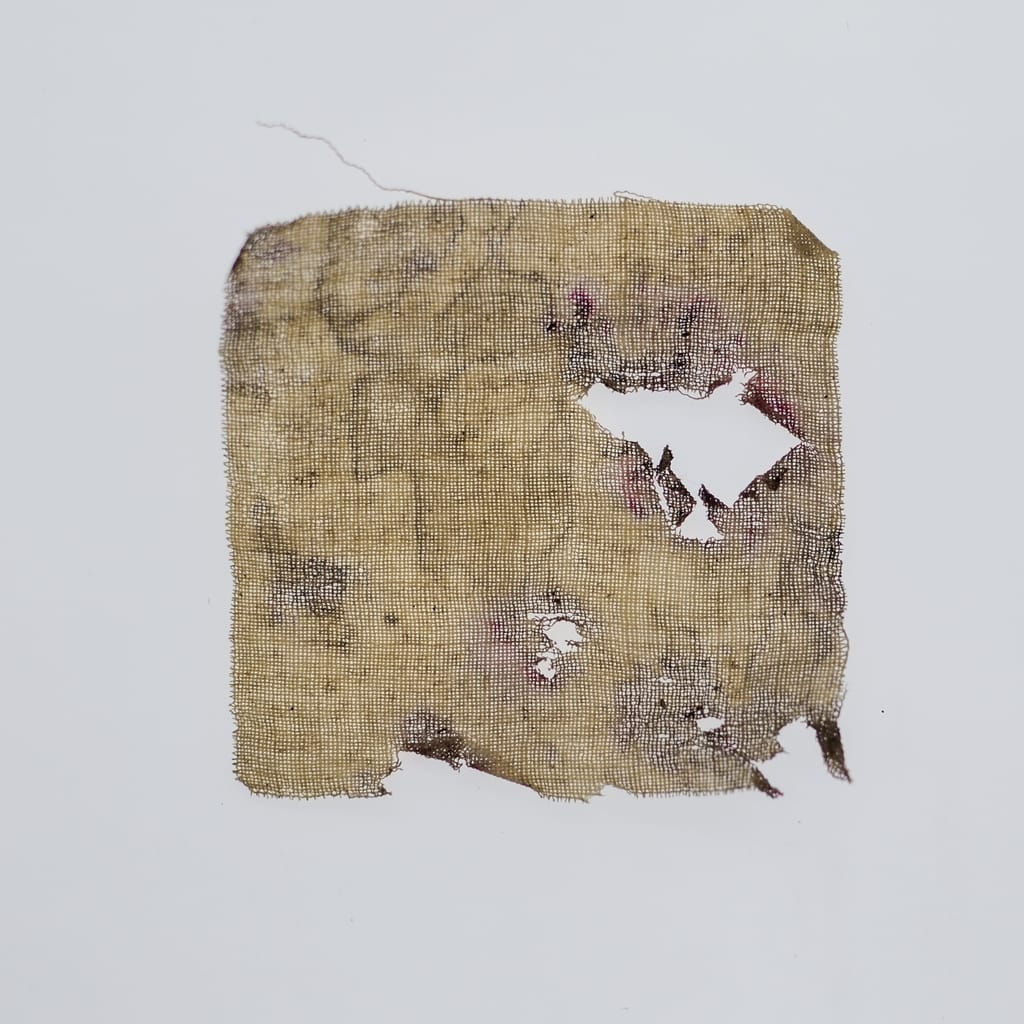

Wool 01

ID:Wool 01

Date:06.06.2023 - 12.09.2023

Material:100% Wool

Fibre:Protein Fibre

Temperature:29°C

Size:

75x75mm

Notes:

Original colour: Ecru, unbleached

<u>More about Wool:</u>

Wool is a protein fibre, derived from hairs of various mammals, such as sheep, goats, rabbits, and camelids. These hairs, after they are collected, carded and spun into yarn to be woven into wool textiles. Prior to domestication, sheep's fleece was more hairy than woolly, though selection by breeders made sheep gradually become woollier.

Its application varies based on its source which directly impacts its coarseness. There are many types of woollen fabrics, such as merino - mostly used for suits and fine knits, to camel wool, which, due to its coarseness, is used more on the outside layers of clothing.

<u>Properties:</u>

Wool is very popular for its excellent thermal insulating properties. Other than that, compared to other cellulose and synthetic textiles, wool is fire-resistant and in contact with fire it chars and self-extinguishes, making it excellent for thermal insulation of buildings.

<u>Decomposition:</u>

As a protein fibre, the decomposition is slow and steady, with minimum time necessary to see any significant deterioration is 3 months. Whilst wool is fully biodegradable, this process, depending on the wool itself, as well as external environments, varies anywhere from 3 months to 2 years (Williams, 2020).

This is mainly because wool is a keratin fibre. Since microbial degradation of keratin is not widespread in nature, keratin can serve as an efficient defence, in this case of sheep, even against microbial attack (Lange et al., 2016). Therefore wool garments have a generally high lifespan and retain relatively good quality than other fibres (Lebedytė & Sun, 2021).

Silk 01

ID:Silk 01

Date:08.08.2023 - 14.11.2023

Material:100% Silk

Fibre:Protein Fibre

Temperature:29°C

Size:

75x75mm

Notes:

Original colour: White

<u>More about Silk:</u>

Silk is the strongest natural protein fibre and is predominantly produced from silkworms, small moths, which spin a silk cocoon that is processed to yield silk fibre, in a process called sericulture.

<u>Properties:</u>

Despite its natural strength, silk is mostly desirable for its luxurious feel and undeniable historical importance. Light weight and soft feel make it a prized fabric for clothing and luxury home furnishings.

<u>Decomposition:</u>

The tested white silk sample did not show any signs of fragmentation in the 14 weeks of testing in mature compost under 29°C. The main difference was its staining, occurring due of the presence of pigmented bacteria and fungi, as well as the pigments from microbial decay.

Polycotton 01

ID:Polycotton 01

Date:03.2024 - 04.2024

Material:65% Polyester, 35% Cotton

Fibre:Blended

Temperature:30°C

Size:

75x75mm

Notes:

Original colour: White

Weight of original sample: 0.35g

<u>More about polycotton:</u>

Many textile products are made from blended yarn fabrics, as the most common is polyester and cotton blends - named polycotton. These are amongst the cheapest and most common fabric used for clothing and domestic use.

<u>Properties</u>

Polycotton utilises the softness and absorbency of cotton fibres, together with the durability, light weight, and crease proofness of polyester - a synthetic fibre.

<u>Decomposition</u>

According to some sources, polyester - a synthetic fabric, will take around 20 to 200 years to decompose, though throughout its end of life it'll most likely break down into microplastics.

Cotton, on the other hand decomposes steadily, under controlled environment withing a month. This contrast, however, wasn't reflected in this experiment. The samples stayed consistent, without any weight reduction.

<u>Seperating blended fibres</u>

A mechanical separation of waste polyester/cotton blended fabric into its constituents is almost impossible since the polyester and the cellulose fibres are completely mixed in the yarn in the fabrics and cannot be separated mechanically. Chemical treatment would be possible, which involves dissolving or depolymerizing one of the fibre components while maintaining the other. Although several concepts have been reported in the literature, this methodology has also its shortcomings. Dissolving polyester from the blended fabrics is currently not economical and environmentally feasible since the polyester can be dissolved by only a few solvents which are both expensive and toxic.

<span class="small">Sources:

Baghaei, B., Compiet, S. and Skrifvars, M. (2020) ‘Mechanical properties of all-cellulose composites from end-of-life textiles’, Journal of Polymer Research, 27(9). doi:10.1007/s10965-020-02214-1.</span>